In today's competitive market, simply creating a great product isn't enough to guarantee success. For small and medium businesses, mastering efficient production is the key to protecting margins and fueling sustainable growth. The core challenge is clear: how can you lower expenses without sacrificing the quality that defines your brand? This requires a strategic approach that goes far beyond simple belt-tightening. To effectively start reducing production costs, it is vital to implement broad strategies aimed at identifying and trimming unnecessary spending across all departments. For a wider view on this, our guide on how to cut business expenses offers a comprehensive starting point for organization-wide savings.

This article, however, drills down specifically into the production process itself. We will move beyond generic advice to offer a deep dive into nine powerful, proven strategies. You'll learn how to implement lean manufacturing principles, leverage targeted automation, optimize your entire supply chain, and integrate smart technology. Each method presented is a crucial pillar for building a more resilient, efficient, and ultimately more profitable manufacturing operation. Prepare to transform your production floor from a necessary cost center into a powerful strategic advantage.

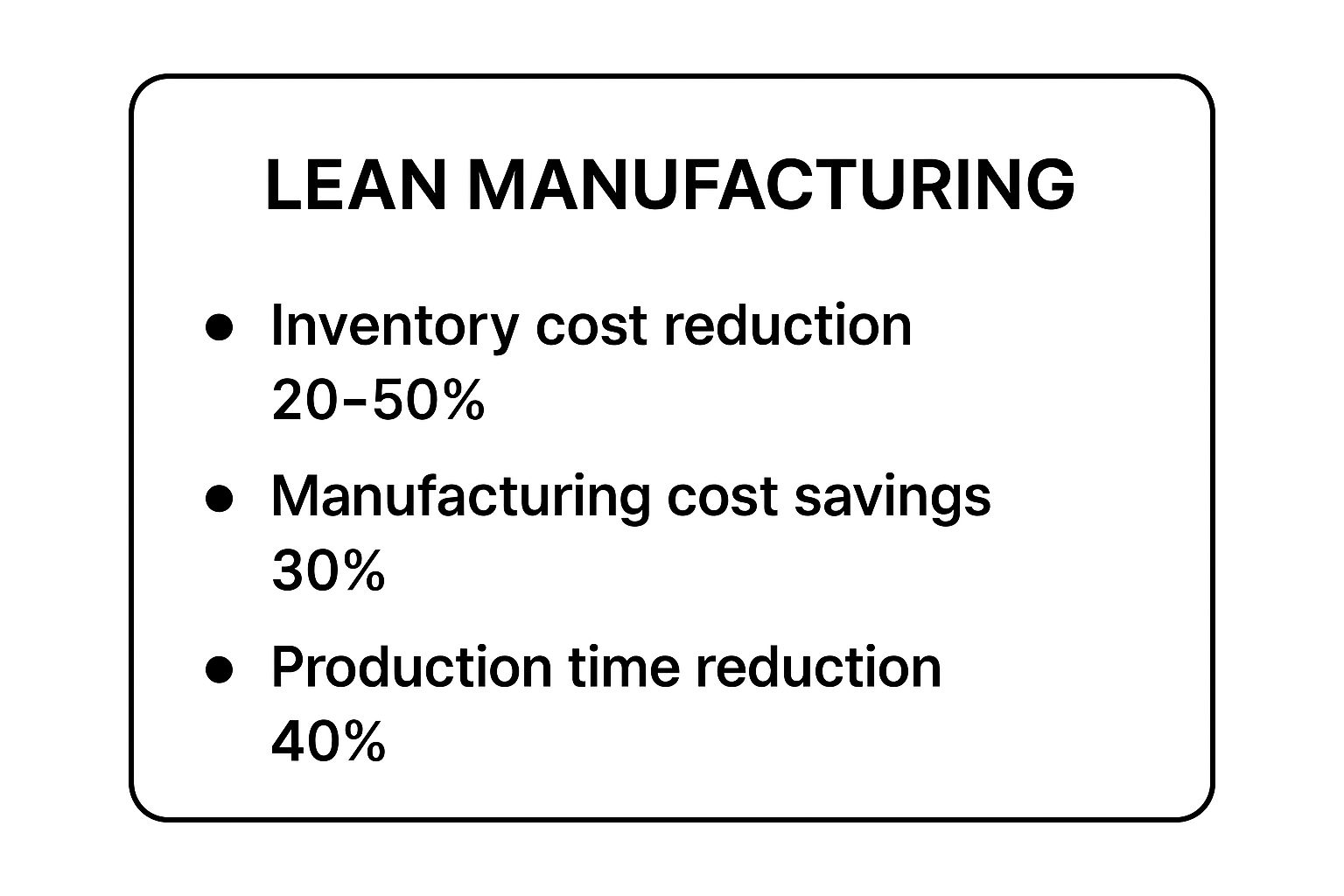

1. Lean Manufacturing: Eliminating Waste, Maximizing Value

Lean manufacturing is a systematic method for minimizing waste within a production system without sacrificing productivity. Originating from the Toyota Production System, this approach focuses on maximizing customer value while using fewer resources. By identifying and eliminating non-value-adding activities, businesses can achieve significant progress in reducing production costs, improving quality, and shortening lead times. The core principle is continuous improvement, or "kaizen," which empowers every employee to contribute to a more efficient process.

Identifying the Eight Wastes of Lean

To implement this strategy, you must first identify the "eight wastes" that drain resources and add unnecessary expenses to your operations.

- Defects: Products or services that require rework or are scrapped entirely. This directly impacts material, labor, and overhead costs.

- Overproduction: Making more of a product than is currently needed, leading to storage costs and potential obsolescence.

- Waiting: Idle time for employees or machinery, often caused by poor workflow, shortages, or bottlenecks.

- Non-Utilized Talent: Failing to use the skills, knowledge, and creativity of your team.

- Transportation: Unnecessary movement of materials or products between processes.

- Inventory: Excess raw materials, work-in-progress, or finished goods that tie up capital and require space.

- Motion: Unnecessary movement by people, such as walking to get tools or information.

- Extra-Processing: Performing work that adds no value from the customer's perspective, like over-polishing a surface the customer won't see.

By conducting a "waste walk" through your facility, you can observe these inefficiencies firsthand and begin formulating a plan for reducing production costs at their source. For instance, a small furniture maker might discover excess inventory waste from batch-producing standard table legs. By shifting to a just-in-time (JIT) system, they produce legs only as orders come in, slashing storage needs and freeing up capital.

2. Automation and Robotics: Enhancing Efficiency and Precision

Automation and robotics involve implementing automated systems, robots, and smart technologies to handle tasks previously performed by manual labor. This strategy ranges from simple conveyor belts to advanced, AI-driven manufacturing processes. By integrating technology, businesses can significantly boost production speed, improve consistency, and achieve a higher level of precision, all of which are crucial for reducing production costs. This approach frees human workers from repetitive, strenuous, or dangerous tasks, allowing them to focus on more complex, value-adding activities.

Key Implementation Strategies

Successfully integrating automation requires careful planning and a strategic approach. Consider these steps to ensure a positive return on investment.

- Start Small and Scale: Begin by automating high-volume, repetitive, and predictable tasks. These processes often offer the quickest wins and a clear ROI.

- Conduct ROI Analysis: Before investing, thoroughly analyze the potential costs versus the expected savings in labor, materials, and error reduction. Factor in maintenance and training expenses.

- Invest in Employee Retraining: Automation changes job roles, it doesn't always eliminate them. Invest in retraining programs to upskill your workforce to manage, program, and maintain the new systems.

- Choose Scalable Solutions: Select automation solutions that can grow with your business. Modular systems, like those from Universal Robots, allow you to add capabilities as your production demands increase.

A powerful example is how Tesla's Gigafactory uses advanced automation to streamline battery pack assembly, reducing battery costs by over 30%. By following a similar, albeit smaller-scale, strategy, your business can leverage technology as a powerful tool for reducing production costs and gaining a competitive edge.

3. Supply Chain Optimization: Enhancing End-to-End Efficiency

Supply chain optimization is the strategic management of the entire network involved in producing and delivering a final product, from raw material suppliers to end customers. This holistic approach focuses on creating a seamless, efficient, and cost-effective flow of goods, information, and finances. By fine-tuning each link in the chain, businesses can achieve substantial progress in reducing production costs, minimizing delays, and improving overall resilience. The goal is to align supply with demand perfectly, eliminating friction and waste at every stage.

Key Strategies for Supply Chain Cost Reduction

To implement this strategy effectively, you must analyze and improve several core components of your supply chain. Focusing on these areas will reveal opportunities for significant savings and enhanced performance.

- Supplier Relationship Management: Go beyond transactional interactions. Negotiate long-term contracts for better pricing and stability, and collaborate with key suppliers on forecasting and inventory planning. A strong partnership can lead to preferential treatment and better terms.

- Logistics and Transportation: Analyze your shipping routes, carriers, and freight modes. Consolidating shipments, utilizing route optimization software, or exploring regional distribution centers can drastically cut transportation expenses, which are often a major cost driver.

- Inventory Management: Implement systems that provide real-time visibility into inventory levels. This allows you to avoid stockouts without carrying excessive safety stock, which ties up capital and incurs storage costs. Techniques like vendor-managed inventory (VMI) can streamline this process.

- Demand Forecasting: Use data analytics and historical sales information to predict future customer demand more accurately. Better forecasting prevents overproduction and underproduction, two major sources of unnecessary costs and lost revenue.

By viewing your supply chain as an interconnected ecosystem rather than a series of separate functions, you can unlock powerful efficiencies. For example, a small electronics company could consolidate its component orders with a few reliable suppliers under long-term agreements, reducing production costs through bulk pricing and lower administrative overhead while ensuring a more stable supply.

4. Energy Efficiency and Resource Conservation

Systematically reducing energy consumption and material waste is a powerful lever for cutting operational expenses. This strategy involves a comprehensive approach, from upgrading to energy-efficient equipment and adopting renewable energy sources to implementing robust recycling programs. By minimizing utility costs and environmental impact simultaneously, businesses can achieve a dual victory of financial savings and corporate responsibility. This focus on resource stewardship is a critical component of a modern strategy for reducing production costs.

Implementing a Conservation-First Mindset

To turn conservation into tangible savings, you must integrate it into your daily operations and long-term planning. For businesses specifically, a deep dive into optimizing energy use within manufacturing and operational settings is crucial for significant cost reductions. You can explore proven strategies for industrial energy efficiency to see how targeted improvements can yield substantial returns.

- Conduct an Energy Audit: The first step is to identify where energy is being wasted. Professional audits pinpoint inefficiencies in lighting, HVAC systems, machinery, and building insulation, providing a clear roadmap for improvements.

- Upgrade and Maintain Equipment: Replace outdated machinery with modern, energy-efficient models. Regular maintenance also ensures that equipment operates at peak efficiency, preventing energy drain from worn-out parts.

- Empower Your Team: Train employees on simple conservation practices, like turning off lights and equipment when not in use. Fostering an energy-conscious culture can lead to significant collective savings with minimal investment.

- Explore Renewable Energy: Consider installing solar panels or entering into Power Purchase Agreements (PPAs) to lock in lower electricity rates and reduce reliance on the grid.

Companies like 3M have demonstrated the immense potential of this approach, saving over $2.2 billion through decades of dedicated resource conservation programs. By focusing on both large-scale upgrades and small behavioral changes, you can effectively lower utility bills, a major factor in reducing production costs for any manufacturer. This also ties into the initial design phase, where making smart choices can prevent waste from the start. Learn more about cost-effective design solutions that incorporate resource efficiency.

5. Outsourcing and Offshoring: Strategic Production Relocation

Outsourcing and offshoring are strategic approaches where businesses delegate specific production processes or functions to external providers or move them to different geographical locations with lower cost structures. This allows companies to tap into specialized expertise, global talent pools, and significant labor cost advantages, which is a powerful method for reducing production costs. By entrusting non-core activities like manufacturing or customer support to a third party, a business can focus its internal resources on core competencies such as innovation, design, and marketing.

Key Strategies for Successful Implementation

To leverage this approach effectively, businesses must move beyond simply finding the cheapest provider and focus on strategic partnership and total value.

- Evaluate Total Cost of Ownership (TCO): Look beyond the sticker price. Calculate the full cost, including logistics, tariffs, communication overhead, quality control, and potential travel. Sometimes a slightly more expensive local provider offers a lower TCO than a cheaper overseas option.

- Start with Pilot Projects: Before committing to a large-scale transfer of operations, test the waters with a smaller, non-critical project. This allows you to evaluate the provider's reliability, communication, and quality without risking a core part of your business.

- Establish Clear Service Level Agreements (SLAs): Define every aspect of the partnership in a legally binding SLA. This document should detail performance metrics, quality standards, delivery timelines, and penalties for non-compliance, leaving no room for ambiguity.

- Maintain Strong Governance and Oversight: Outsourcing does not mean abdicating responsibility. Appoint an internal manager or team to oversee the relationship, conduct regular performance reviews, and ensure the provider remains aligned with your strategic goals.

Companies like Nike, which outsources 100% of its footwear production, demonstrate how this model enables a sharp focus on high-value activities like branding and R&D. For small businesses, this could mean outsourcing assembly to a specialized local firm to scale up production without investing in expensive new equipment. Effective vendor management is crucial for success, ensuring these partnerships contribute directly to reducing production costs and enhancing efficiency. To dive deeper, you can learn more about vendor management best practices.

6. Process Standardization and Optimization

Process standardization is the systematic method of establishing and documenting a single, best way to perform any given task or process. By creating repeatable, optimized workflows, businesses eliminate variability, reduce errors, and create a predictable production environment. This approach focuses on analyzing every step of a process to remove inefficiencies and ensure consistent output. Implementing standardized work is a cornerstone for reducing production costs because it provides a stable baseline from which to measure and implement future improvements.

Key Strategies for Standardization

To effectively standardize your operations, focus on analyzing and documenting your current state to identify opportunities for improvement. This creates a foundation for consistent, high-quality results.

- Process Mapping: Use tools like value stream mapping to visually outline every step of a production process. This helps identify bottlenecks, redundant activities, and areas of waste that are often hidden in day-to-day operations.

- Involve Frontline Workers: The employees who perform the tasks daily have invaluable insights. Involve them directly in creating and refining the standards to ensure they are practical, efficient, and gain widespread acceptance.

- Implement SMED: Single-Minute Exchange of Die (SMED) is a technique focused on drastically reducing the time it takes to switch a production line from one product to another. Minimizing this changeover time cuts machine downtime and increases available production capacity.

- Regularly Review and Update: Standards are not meant to be permanent. Establish a schedule for reviewing and updating documented processes to incorporate new learnings, technologies, and improvements, ensuring continuous optimization.

By applying these principles, you create a robust framework for efficiency. For example, Intel’s "Copy Exactly!" methodology ensures that every one of its global fabrication plants uses identical processes, guaranteeing consistent chip quality and performance regardless of location. For a deeper look into this topic, you can learn more about Process Standardization and Optimization and how to apply it to your business.

7. Economies of Scale: Lowering Unit Costs Through Volume

Economies of scale is a powerful economic principle where the per-unit cost of production decreases as the volume of output increases. This advantage arises because fixed costs, like factory rent or machinery, are spread over a larger number of units. By strategically scaling up operations, businesses can achieve a significant competitive edge through lower prices, higher margins, or both, making this a cornerstone strategy for reducing production costs over the long term.

Leveraging Volume for Cost Advantages

Implementing this strategy involves more than just producing more; it requires a deliberate approach to maximizing the benefits of increased scale.

- Purchasing Power: Buying raw materials in bulk often unlocks substantial discounts from suppliers. Negotiating tiered pricing based on volume ensures that as your production grows, your input costs shrink.

- Operational Efficiency: Higher production volumes justify investments in more efficient, automated machinery and streamlined workflows. This reduces labor cost per unit and minimizes production time.

- Fixed Cost Distribution: Your fixed costs, such as administrative salaries or equipment leases, remain relatively constant regardless of output. Producing more units means each one carries a smaller share of this overhead.

- Specialization: Larger operations allow employees to specialize in specific tasks, increasing their speed and proficiency. This division of labor enhances overall productivity and reduces errors.

A prime example is how Henry Ford's assembly line for the Model T revolutionized manufacturing. By scaling production to unprecedented levels, he drastically lowered the cost of each vehicle, making cars affordable for the masses. This demonstrates how a commitment to scale is fundamental to reducing production costs. To effectively manage this growth, robust capacity planning is essential. You can explore effective capacity planning strategies on creativize.net to ensure your infrastructure can support increased demand without creating new bottlenecks.

8. Six Sigma and Quality Management

Six Sigma is a disciplined, data-driven methodology focused on eliminating defects and improving processes to a near-perfect level. The core goal is to achieve a process where 99.99966% of all opportunities to produce a feature of a part are statistically expected to be free of defects. This translates to just 3.4 defects per million opportunities (DPMO). For businesses aiming for the highest standards of quality, implementing Six Sigma provides a structured path to reducing production costs by systematically minimizing errors, waste, and process variations.

The DMAIC Framework for Process Improvement

The most common Six Sigma methodology for improving existing business processes is DMAIC, a five-phase, data-driven improvement cycle. Following this framework ensures that solutions are based on evidence, not guesswork.

- Define: Clearly identify the problem, the project goals, and the specific customer deliverables. What exactly are you trying to improve, and how will you know when you've succeeded?

- Measure: Collect data to establish a baseline for current process performance. This step is crucial for quantifying the problem and setting realistic improvement targets.

- Analyze: Use statistical analysis to investigate the root causes of defects and process inefficiencies. Why is the problem occurring?

- Improve: Implement and test solutions to eliminate the root causes identified in the analysis phase. This often involves process redesign or optimization.

- Control: Establish control measures to sustain the gains achieved. This ensures the process does not revert to its old, inefficient state over time.

By applying the DMAIC framework, a company can systematically tackle its most costly quality issues. For example, General Electric famously saved over $12 billion in its first five years of Six Sigma implementation by applying this rigorous approach to everything from manufacturing to financial services. Properly measuring project success is fundamental to this control phase.

9. Technology Integration and Industry 4.0

Industry 4.0 represents the fourth industrial revolution, characterized by the integration of advanced digital technologies into manufacturing processes. By implementing tools like the Internet of Things (IoT), artificial intelligence (AI), and data analytics, businesses can create smart, connected production systems. This digital transformation provides real-time insights, automates complex decisions, and predicts operational needs, offering a powerful avenue for reducing production costs and boosting efficiency. The core idea is to build a "smart factory" where machines, systems, and people communicate seamlessly.

Key Technologies for a Smarter Factory

To leverage Industry 4.0, focus on integrating technologies that offer the greatest return on investment for your specific operational challenges.

- Internet of Things (IoT) Sensors: These devices collect real-time data from machinery on performance, temperature, and vibration. This information is crucial for monitoring operations and enabling predictive maintenance.

- Artificial Intelligence (AI) and Machine Learning: AI algorithms analyze vast datasets to identify patterns, predict equipment failures, optimize production schedules, and improve quality control, far beyond human capability.

- Big Data Analytics: This involves processing and analyzing the massive amounts of data generated by IoT sensors and production systems to uncover inefficiencies and opportunities for cost savings.

- Robotics and Automation: Advanced robotics can handle repetitive, precise, or dangerous tasks, increasing throughput, reducing labor costs, and minimizing human error.

Implementing these technologies allows for a proactive rather than reactive approach to manufacturing. For example, Rolls-Royce utilizes IoT sensors and predictive analytics on its aircraft engines to foresee maintenance needs, reducing production costs related to unexpected downtime and repairs by up to 25%. Similarly, a small CNC machine shop could install IoT sensors on its key equipment to predict when a cutting tool will fail, scheduling a replacement just in time to avoid a costly production halt and ruined materials.

Cost Reduction Strategies Comparison Table

| Strategy | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Lean Manufacturing | Medium to High | Moderate (training & culture) | Waste reduction, 20-50% inventory cost savings | Manufacturing seeking efficiency & quality | Continuous improvement, reduced lead times |

| Automation and Robotics | High | High (capital & expertise) | Labor cost reduction (15-30%), 24/7 operation | High-volume, repetitive, hazardous tasks | Consistency, speed, error reduction |

| Supply Chain Optimization | High | Moderate to High (planning tools) | Procurement, inventory & transport cost savings | Complex supply networks needing cost reduction | Enhanced visibility, risk management |

| Energy Efficiency & Resource Conservation | Medium to High | Moderate to High (equipment & tech) | Energy cost reduction 10-30%, sustainability | Companies aiming to reduce utilities & waste | Long-term cost stability, government incentives |

| Outsourcing and Offshoring | Medium | Low to Moderate (management focus) | Labor cost cut 40-70%, access to global talent | Cost-sensitive production & scalability | Focus on core business, faster market entry |

| Process Standardization & Optimization | Medium | Moderate (analysis & training) | Defect reduction, 15-25% productivity boost | Environments needing consistent, repeatable work | Easier training, facilitates automation |

| Economies of Scale | Medium | High (capital & volume focus) | Significant cost per unit reduction | Large-scale production & supplier negotiation | Competitive pricing, market share growth |

| Six Sigma and Quality Management | High | Moderate to High (training & tools) | Defect cost reduction 50-90%, customer satisfaction | Businesses focusing on quality & defect reduction | Data-driven, culture of continuous improvement |

| Technology Integration & Industry 4.0 | High | High (tech investment & skills) | Maintenance cost cut 10-40%, real-time control | Smart factories embracing digital transformation | Predictive quality, energy optimization |

From Strategy to Action: Building Your Cost Reduction Roadmap

The journey toward reducing production costs is not a sprint with a defined finish line; it is a continuous marathon of strategic improvement. Throughout this guide, we’ve explored a powerful arsenal of nine distinct yet interconnected strategies, from the waste-eliminating principles of Lean Manufacturing to the data-driven precision of Industry 4.0. The path to a more profitable and resilient operation doesn't involve implementing every single idea at once. Instead, true transformation begins with a focused, deliberate approach.

The most successful businesses view cost optimization as an integral part of their operational culture, not a one-off project. It’s about building a system where efficiency is a shared responsibility and a constant pursuit. The strategies discussed, including supply chain optimization, process standardization, and Six Sigma, are not just theoretical concepts. They are practical frameworks that empower you to look at your entire production workflow with fresh eyes, identifying hidden inefficiencies and untapped opportunities.

Your Immediate Next Steps: Creating a Phased Plan

The key is to translate these insights into a tangible action plan. Don't let the scope of possibilities lead to paralysis. Instead, build momentum by targeting high-impact areas first.

Here is a simple, actionable roadmap to get started:

- Conduct a Quick Audit: Begin by evaluating your current operations against the nine strategies. Which areas present the most significant challenges or opportunities for your business right now? Is it high energy consumption, inconsistent product quality, or bottlenecks in your supply chain?

- Select Your Top Priorities: Choose just two or three strategies that offer the most immediate and substantial return on investment. For example, if labor costs are your primary concern, focusing on Automation and Process Standardization would be a logical starting point.

- Launch a Pilot Project: Before committing to a company-wide overhaul, test your chosen strategy on a smaller, manageable scale. This allows you to measure results, work out any issues, and build a strong business case for broader implementation. A successful pilot creates the proof and the confidence needed to secure buy-in from your entire team.

- Engage Your Team: Your frontline employees are your greatest resource. Involve them in the process from the very beginning. They possess invaluable, on-the-ground knowledge of daily operations and can offer practical solutions that leadership might overlook. Fostering this collaborative environment is critical for sustainable change.

By systematically embedding these principles into your daily operations, you are not just cutting expenses. You are building a more agile, competitive, and robust business prepared to navigate market fluctuations and seize future opportunities. Mastering the art of reducing production costs is an investment in your company's long-term health and success, creating a foundation for sustainable growth and profitability for years to come.

Ready to tackle your creative production costs? While you optimize your operations, let Creativize handle your design needs with a flexible, on-demand subscription. Access top-tier creative talent without the high costs and overhead of traditional hiring by visiting Creativize to see how we can streamline your design workflow today.